Article

The EU Battery Passport – Manage Data Requirements, Navigate Approaching Deadlines, and Leverage Strategic Advantages

1 December, 2023

Supply chain transparency, access to reliable data, and industry collaboration are key concepts in preparing for the EU Battery Regulation’s Battery Passport requirements. Though the deadlines might seem distant, to comply companies will need to securely incorporate and manage vast and complex data sets, provide a streamlined approach to transparency and an in-depth understanding of supply chain complexities beyond immediate suppliers. Battery Passport solutions, such as RCS Global’s Claritas, are already being piloted and developed. The clock is ticking—act now to navigate the paradigm shift and position yourself at the forefront of compliance and market leadership.

In the evolving landscape of electric mobility, a new regulatory milestone has been reached: the EU Battery Regulation. Among the various requirements of this new regulation, the mandate to establish a comprehensive Battery Passport looms on the visible horizon, requiring special attention from OEMs and EV battery manufacturers.

Similar to a real passport, the Battery Passport will be an immutable digital ledger, a record of the journey the raw materials have taken, where and how they were extracted and processed, and information about its lifecycle. It is a promise of transparency, sustainability, and accountability.

By February 18, 2027, OEMs and EV battery manufacturers falling within the regulatory scope will be responsible for ensuring that Battery Passports have been issued for their batteries. Given the overwhelming amount of data that will need to be included in this Battery Passport – most of which is still far from being collected as of today – it is imperative that affected companies already start adapting their processes and begin engaging their supply chains. Understanding the specific data requirements for collection and disclosure is critical, laying the groundwork for compliance when it transitions from concept to reality.

Data Requirements and Levels of Disclosure

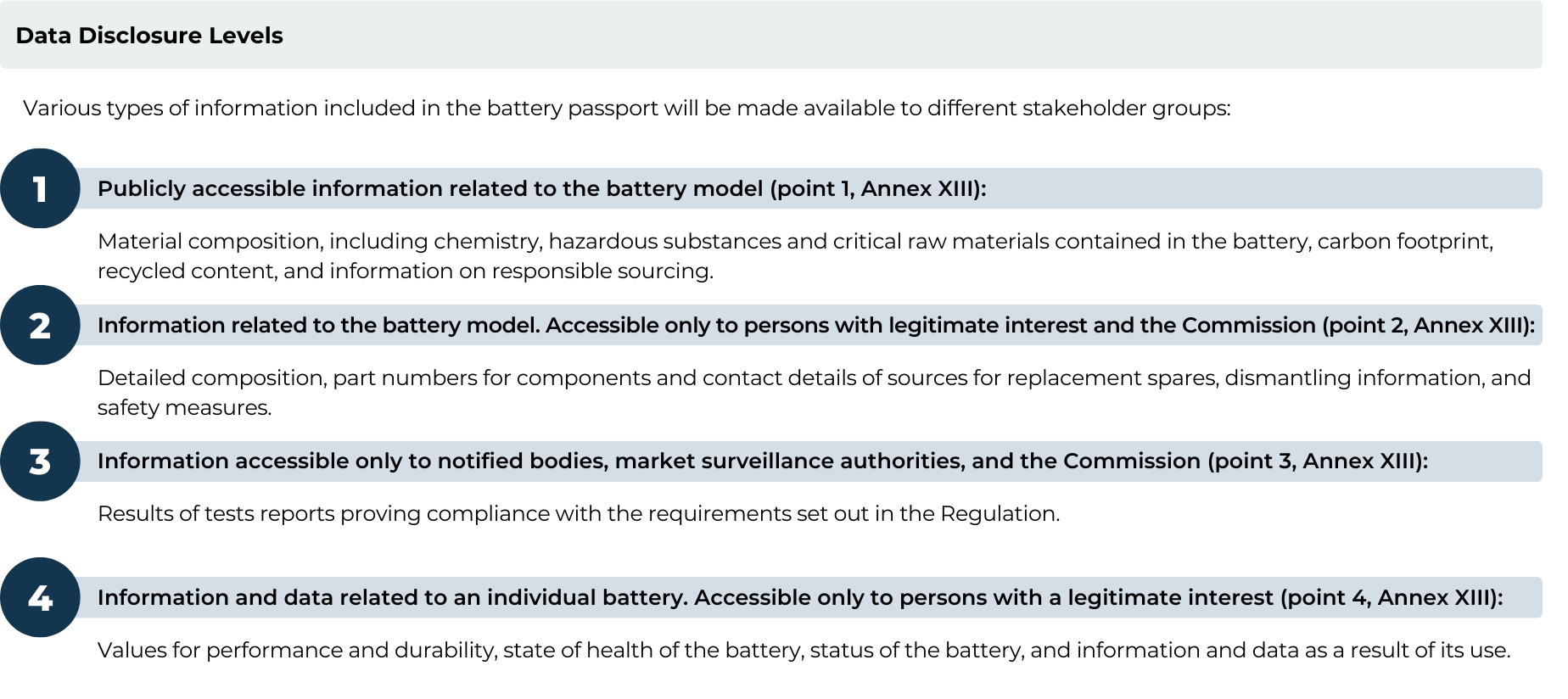

Publicly accessible information will range from basic manufacturer information, material composition and chemistry of the battery, detailed carbon footprint information to demonstration of supply chain due diligence, ensuring every consumer can gauge the environmental and social impact at a glance. The data will extend to include responsible sourcing reports, recycled content information or waste management information, providing an unprecedented level of traceability and sustainability assurance. Further technical specifics such as rated capacities, voltage ranges, power capabilities, expected lifetime, and energy efficiency metrics will also need to be made available. Many of these data points are dynamic, meaning they change over the lifetime of a battery, and therefore require a management system that can track the changes.

Beyond public scrutiny, a layer of detailed information will be exclusively accessible to those with a legitimate interest, including the intricate composition of cathodes, anodes, and electrolytes. Dismantling information will require comprehensive documentation, including exploded diagrams, dismantling sequences, and safety measures – essential for end-of-life processing and recycling initiatives.

Notified bodies, market surveillance authorities and the EU Commission will have eyes on the core compliance data through test reports and performance benchmarks. This tier of the Battery Passport is a testament to accountability, ensuring every battery in circulation meets the stringent standards set forth by the EU.

At an individual level, each battery’s history will be chronicled, noting performance metrics, state of health, and lifecycle status, whether original, repurposed, or remanufactured. Operational data, including environmental conditions and charge cycles, will paint a detailed operational portrait of the battery’s life.

This level of detail highlights the imperative for manufacturers to establish sophisticated tracking systems, incentivising disclosures, capable of managing and safeguarding sensitive data while facilitating legitimate access.

Navigate the Approaching Deadlines

The data required to populate the Battery Passport will need to be gathered from a myriad of touchpoints in a battery’s journey—from raw material extraction to the assembly of the final product. This data journey means not only engaging with different units and teams within the manufacturing company, but also engaging with suppliers to ensure that they, too, are prepared to provide the necessary information that spans the entirety of the battery’s life cycle. This intricate web of data requires an unprecedented level of collaboration and transparency across multiple raw materials supply chains.

Unfortunately, most of the companies falling under the scope of the EU Battery Regulation do not currently have the processes and tools necessary to collect all the required data for inclusion in the Battery Passport. Despite this fact, the initial requirements leading to the implementation of the Battery Passport will become mandatory well before February 2027.

By August 2024, OEMs and EV battery manufacturers are expected to provide values for electrochemical performance and durability parameters with every battery placed on the market and to include data for determining the state of health and expected lifetime of a battery in the battery management systems.

Carbon footprint declarations shall be drawn up for every battery by February 2025, and from August 2025 on, economic operators that place batteries on the market or put them into service shall fulfil the due diligence obligations as outlined in the Regulation.

To comply, OEMs and EV battery manufacturers must thoroughly explore their supply chains, requiring data that many suppliers may not currently track or be willing to disclose, or if they do, not at the level of detail that the Battery Passport will require.

Establishing a streamlined data flow will be a time-intensive and meticulous task. This is not a mere collection of receipts and specifications; it requires the validation of environmental impacts, the verification of responsible sourcing, and the assessment of recyclability. Manufacturers must ensure that their suppliers can consistently and reliably deliver data that meets the EU’s stringent criteria.

There’s also a critical need for educating and training across the supply chains. Suppliers must understand the importance of their data, the specifics of what is required, and how it fits into the larger picture of sustainability and regulatory compliance.

Seizing the Opportunity: Why Early Adoption Matters

The risk of inaction is high. Failure to act will result not only in non-compliance but also in potential exclusion from a growing market that is increasingly demanding sustainable and transparent practices. Customers, investors, and regulators are watching and will hold companies accountable for the environmental and social footprint of their products. Authorities can even prohibit the commercialisation of non-compliant batteries or get them withdrawn from the EU market.

Beyond compliance, there is a strategic advantage to early adoption. Companies that take the lead in implementing these systems will not only be ahead of the regulatory curve, they will also be positioned as leaders in the eyes of consumers who increasingly value sustainability. Furthermore, these first-mover companies may have a chance to help shape the systems and standards that are still being developed today.

The Battery Passport is not a distant obligation, but an imminent shift in the industry’s operating paradigm. It is a call to take a proactive stance to reinvent supply chains, promote data transparency and embed sustainability into the DNA of every battery. The road to compliance is complex but navigable with a proactive approach – and the time to start is now.

How Can RCS Global Help?

Building on over 16 years of expertise as a leader in data-driven ESG performance, responsible sourcing, and mining assurance, RCS Global Group introduces Claritas – a cutting-edge digital solution and Battery Passport programme designed to track battery raw material supply chains and ensure full compliance with the EU Battery Regulation.

Responding to the outlined regulatory requirements, a Battery Passport will have to operate simultaneously as a database and a data exchange system including both centralised and decentralised governance. To facilitate this, Claritas utilises a system of self-sovereign identity and digital wallets applied to the battery raw materials supplier ecosystem.

The Claritas platform and underlying data exchange services will facilitate the creation of a Battery Passport with all required data attributes, including validated responsible sourcing and Product Carbon Footprint data. The platform’s high level of customization ensures adaptation to “potential” future legislative requirements and extending traceability beyond the materials listed in the EU Battery Regulation. Claritas users will have the capability to issue Battery Passports with consistent data sets, meeting both EU and US regulatory demands for EV batteries.

Interested in learning more about Claritas Battery Passport?

Want to learn more about the EU Battery Regulation?

Get in touch and get full access to a comprehensive 20-page analysis and commentary on the EU Battery Regulation written by our responsible sourcing experts.

Authors

Sabrina Jeckelmann

Project Manager

Javier Sánchez

Project Manager