Measure and improve suppliers’ ESG performance

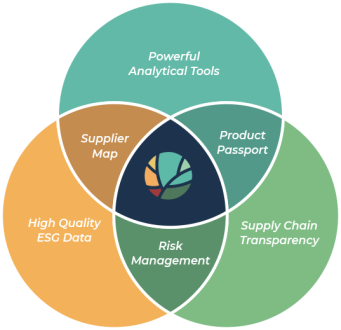

Vine is a due diligence platform that enables transparency and regulatory conformance through the discovery and visualisation of global supply chains. Its unique data and insights empower users to actively manage risk and drive supplier ESG performance improvements.

-

At Stellantis, we are committed to due diligence to comply with social standards throughout the supply chain. A part of this commitment is ensuring transparency with suppliers and Vine plays a central role on this journey. With Vine, we are able to visualise and get a quick overview of our complex battery supply chain step-by-step all the way to the mine sites. Through Vine, we gain high-quality, validated data that we can turn into knowledge to help inform prioritisation, supply chain management, and stakeholder engagement. The transparency gained through Vine further supports compliance with various regulatory requirements and enables us to take responsibility in our battery supply chain seriously.

Erik RicherCorporate Social Responsibility Correspondent

Utilise a database of over 2300 confirmed and audited suppliers

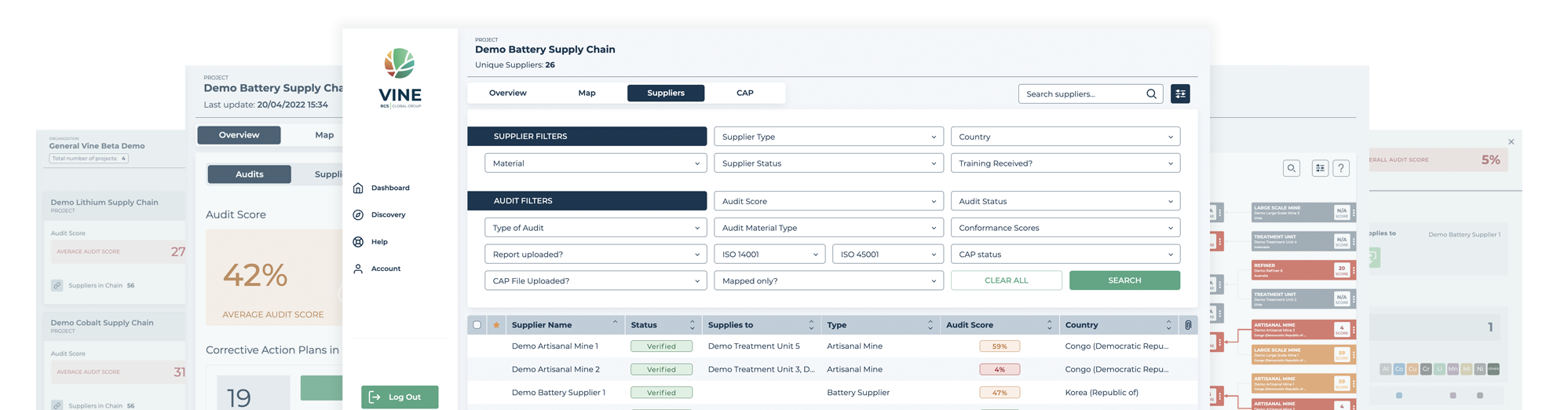

With over 2300 verified suppliers in the EV battery and battery storage supply chains already in the platform’s database and more being added every month, Vine is rapidly scaling and becoming the most comprehensive database for supplier ESG performance in the battery raw materials sector.

Process complexity, collaborate efficiently, and communicate

Supply chain due diligence is a complex, resource-intensive process. Vine empowers responsible sourcing teams, digitalising their manual work processes and boosting their supply chain due diligence and risk management capabilities. Vine has an intuitive navigation of supply networks that builds on extensive feedback from the industry to ensure a seamless and easy user-experience.

Discover and visualise your entire supply chain

Vine enables users to map and connect suppliers to better understand complex raw material supply chains. As a visualisation tool, Vine builds full transparency in new or unique supply chains.

Access validated supply

chain data to inform insights

Vine is built from high-quality datasets based on RCS Global’s expert audits and confirmed supplier disclosures. The Vine Supplier Map is created on the basis of confirmed material flows and links between entities. Get insights that can be utilised for analysis, decision making and reporting to internal and external stakeholders based on reliable data. Demonstrate positive supply chain impact through continuous improvement that can be reported.

Manage supply chain risk

and drive supplier ESG performance improvements

Vine provides structure for supplier engagement and risk mitigation, including corrective action management. Dive deeper into your supply chain, analyse specific supply chain links, and identify weakest performers, red flags and points of improvement to optimise your supply chain’s ESG improvement.

Demonstrate and report conformance with regulatory requirements and stakeholder expectations

Rely on validated ESG performance data based on audits pegged against internationally recognised standards. Vine will also allow you to connect to Better Mining assured data from upstream certified artisanal mine sites in 3TG, copper and cobalt.

LEARN MORE ABOUT VINE

WHY WE ARE DIFFERENT

Vine is built on RCS Global’s 16 years of leadership and expertise in responsible sourcing and supply chain risk management and has combined it into one, powerful digital tool.

Our expert team of auditors are relied upon by world leading corporations at all tiers of the value chain to deliver certifications and verified audits for all current responsible sourcing programs worldwide. Vine also benefits from our unique upstream knowledge based on our on-the-ground mineral agnostic programme, Better Mining, that runs incident management to improve responsible artisanal small-scale mining.